How The Sausage Gets Made: Lessons from a Sausage Making Class

By Ian MacAllen on Tuesday, November 25th, 2025 at 3:25 am

Sausage-making has been a euphemism for uncleanliness since 1869 when John Godfrey Saxe declared in the The Daily Cleveland Herald that laws and sausages “cease to inspire respect in proportion as we know how they are made.” But I decided I wanted to know anyway, so I ended up taking a class.

The journey began last year when my brother finally received his long overdue wedding present from our mother. She insisted on buying him a KitchenAid Stand Mixer. She believes it is an essential tool for any home, and I had received one as a wedding gift too.

For my brother, it was a bit more complicated. He was married in France and living in Europe. The options at the time were committing to the European electricity standards, or waiting. He waited.

Five years ago, he and his wife moved back from Europe. If you’re good at math, you’ll realize this was during the first pandemic year. Several years would pass before my mother finally brought them the stand mixer.

What makes these mixers especially useful are attachments that perform special functions. I regularly use mine to flatten sheets of pasta noodles. In this, I have found two failings. First, I once lost a race with to produce pasta with my friend who had a dedicated pasta making machine; and two, it simply couldn’t make lasagna sheets big enough for the Don Angie spiral lasagna. But those faults aside, it’s very good at pressing out pasta sheets.

As for my resourceful brother, he soon found himself in possession of a meat grinder attachment acquired through Facebook Marketplace: For sale: meat grinder, never ground.

The mechanism serves all sorts of functions like grinding meat for steak tartare, customized burger mix, and homemade meatballs. My brother decided to attempt making sausage. He had mixed results.

To improve his luck, as a Christmas present, I found him a sausage-making recipe book and purchased a gift certificate for a sausage making class from The Meat Hook. At the time, most of the sausage making classes were offered out of the shop location down the street from my apartment, and I suggested that I would join him for the class when he finally scheduled one.

Nine months later he shot me a text message that he had finally secured a spot. Little did I know, The Meat Hook had opened a second location in Carroll Gardens, not exactly walking distance, but I agreed to sign up too.

We arrived at the shop and were led downstairs into the classroom, the butchery station. The whole place was one of the cleanest food preparation areas I’ve ever seen.

They provided us with a light snack of beer cheese, crackers, and charcuterie while we waited for the other students, and provided us with aprons to keep us clean.

The class was led by Steve Young, a butcher and manager at the shop responsible for producing a lot of the shop’s sausages. I’ve sampled quite a few flavors of sausages from The Meat Hook over the years. The store has standard sweet and spicy Italian sausages, but also more unique offerings like Merguez and custom inventions.

In the class session, we were going to learn to make sweet and hot Italian sausage, both standard sausages in city grocery stores. The meat filling would be cut from the same piece of pork, with the spice recipe determining the sweet and hot.

Steve brought out a large tray of pork pieces and began breaking it down into fat and lean meat. The goal is to get a ratio of 70% lean to 30% fat. Pork is an easy choice because there’s plenty of fat to go around, while leaner animals like goat might not need supplemental fat. Steve prefers pork fat as a supplement, but that doesn’t necessarily work with every dietary restriction.

A successful sausage will balance fat, salt, and moisture. The salt will ultimately act like a binder, releasing moisture from the meat. Moisture also becomes important when considering the types of fillings beyond meat. For instance, adding vegetables, or substituting plant-based fillers.

For pork, the butt or shoulder are the best cuts, according to Steve. But using leaner cuts means adding extra fat, which is also fine to do. The ratio is what matters.

We then weighed out the meat into 10 pound portions, selecting about 7 pounds of lean meat and 3 pounds of fat. However, this isn’t a baking competition. If the measurements are imperfect or there’s slightly more than 10 pounds of meat, the recipe won’t fall apart.

Then it was time to grind.

The industrial machines are much larger than the tabletop grinder that attaches to the stand mixer, but the concept is similar. We shoved meat in the top and then pushed it through an extruder. In class, we were instructed to hold up a splash tray to keep the meat from shooting out of the grinder too far.

We ground the meat twice. The grinding is about texture but also about mixing together the fat and lean meat.

It’s important though not to overheat meat in the grinder though because the fat will begin to melt and separate out of the sausage. On the industrial scale, they typically will let the grinder cool down between batches.

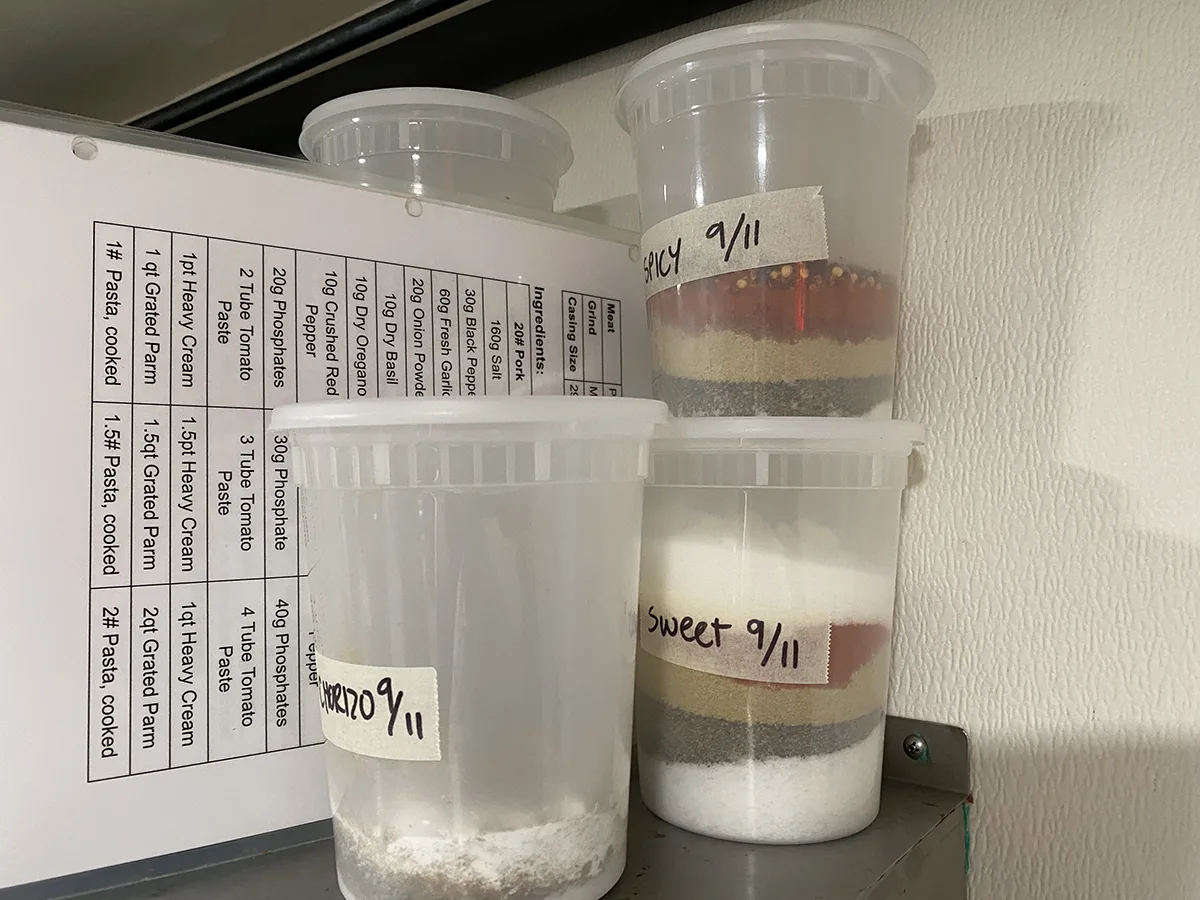

The next step was mixing in the spices that flavor the sausage. In our case, the spice mixes were prepared ahead of time according to the shop’s recipe for sweet and hot Italian sausages.

The spice mix is probably the place where individual sausage makers can distinguish themselves the most. Once you have mastered the physical techniques of filling sausages, flavoring becomes an interesting palate to paint with.

We also added a bit of water to the mixture to get the right consistency.

Our class took turns mixing in the spices, and then it was time to fill the casings.

We used natural casings, meaning they were made from pig intestines. Other animal intestines are sometimes used as well, but result in different size sausages based on the circumference, with sheep producing smaller sausage links and cows much larger.

There are also artificial sausage casings. Typically these are removed before eating. There are some newer kinds of plant-based casings also, but generally our sausage king of Carroll Gardens recommends using natural casings. Natural casings are also one of the more expensive elements of sausage making.

The shop has filling machines that push meat into the casing. The stand mixer has a separate attachment that can be used for this task, but after using the professional grade machine, I can say it might be worth the investment in the extra hardware.

The canister is first filled with meat.

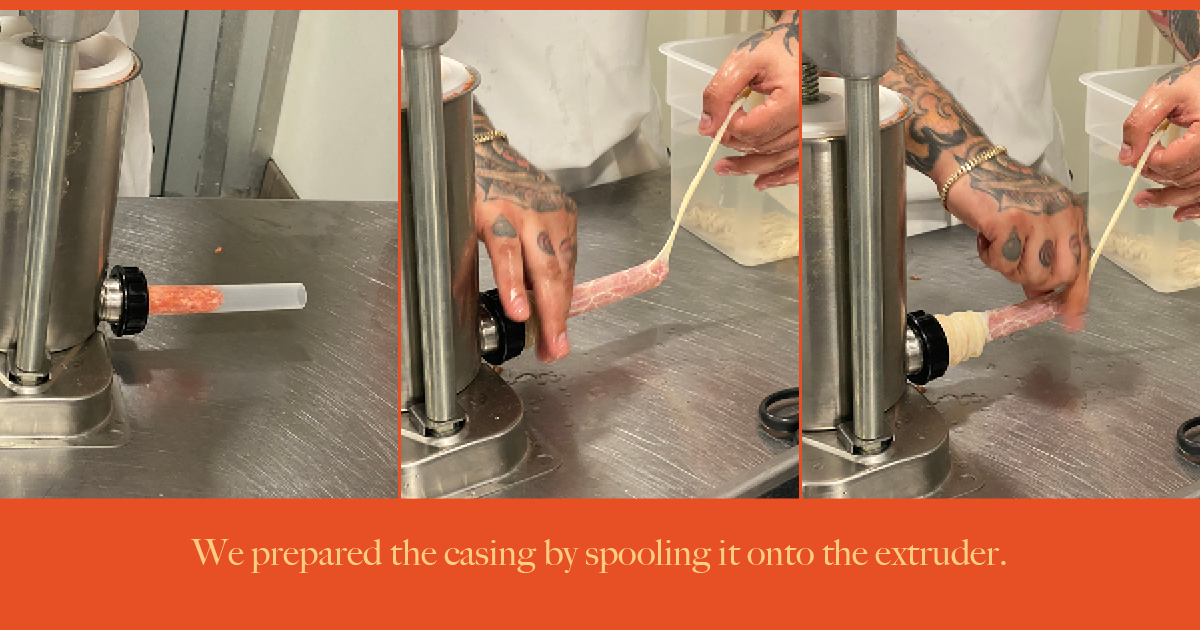

Then the casing has to be attached to the extruder. The casings are soaked in water and unfurled from their packaging onto the extruder nipple. The far end is pushed all the way back to the machine, and then we have a lead that comes off the end that can be held.

The goal is to gently cradle the underside of the casing as the extruder pushes meat into it. Hold it with too much tension and the casing will rip. Not hard enough, and air can get into the sausage.

Steve split the class into two groups, one to make hot sausage and one to make the sweet. There were two stuffing machines. My brother and I were lucky enough to pair up with Lindsay, a brewery owner from Long Island who wanted to learn the sausage making trade.

The three of us filled two and a half casings with the ten pound sausage mix forming big spirals on the table in front of us. We only popped one hernia in the process and quickly tied off the end and started over.

After the casings are filled, the sausages are pricked with tiny holes to help release trapped air. These are specialty devices with thing tines, so you shouldn’t simply use a fork for this process.

The sausages were technically finished at this point and could be grilled up and served.

However, sausage links are much easier to cook, especially on a stove at home. So we twisted each link from the longer sausage by measuring a link, and then squeezing the filling away to have some slack in the casing.

We then twisted the sausage to tighten the casing into place. Alternating twisting directions on each case helps hold them in place.

Afterward, Steve divided up the sausages and we all took home a few links from the hot and sweet piles.

Fresh sausage can keep about a week in the refrigerator, or frozen.

I cooked up the hot Italian sausage to go with a tomato sauce and rigatoni.

After learning how the sausage is made, I’m still interested in eating them. I also am curious now about craft sausages. The possibilities for flavor extend far beyond the traditional Italian sausages that are typical in New York supermarkets, and of course I have some ideas of my own on how to alter even these basics.

I’m also still interested in making aged or smoked sausages, both of which are slightly more complicated and vary quite a bit. And of course, until then, I can always find an interesting selection of sausages at The Meat Hook.

***